Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

We only supply tested, proven components — no guesswork, no shortcuts. Our Forged GR6 GTR Transmissions are built around the Linney HD and Formula 1–6 gearsets, engineered for extreme power and precision. Each unit is blueprinted, upgraded, and built entirely in-house, with flawless performance proven in Time Attack UK and at Race Wars UK with 8-second quarter and full mile consistent passes.

We also offer Dodson Motorsport components as an option, including clutches and gearsets, for customers who want trusted alternatives based on their build goals. Whether it’s for road, track, or drag — our GR6 solutions deliver reliability where it matters most.

1. Stock GR6 Has Its Limits

The factory GR6 handles around 800+bhp — beyond that, stock internals become a known failure point under hard launches or aggressive use.

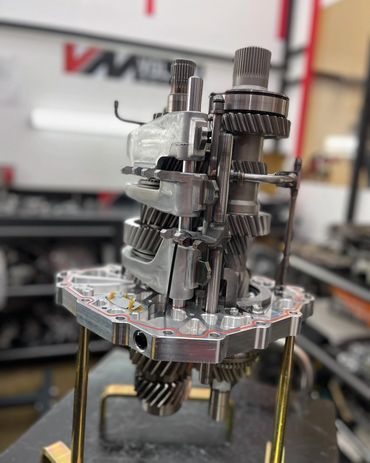

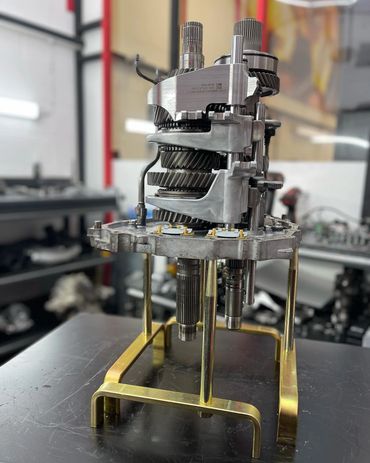

2. Forged Gearsets = Core Strength

We use Linney HD / Formula 1–6 and offer Dodson Extreme gearsets for extreme torque, and long-term durability.

3. Clutch & Basket Upgrades

Forged builds include heavy-duty clutches, billet baskets, and reinforced components to manage aggressive launches and big power.

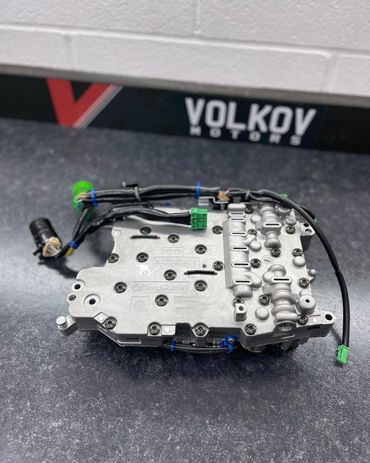

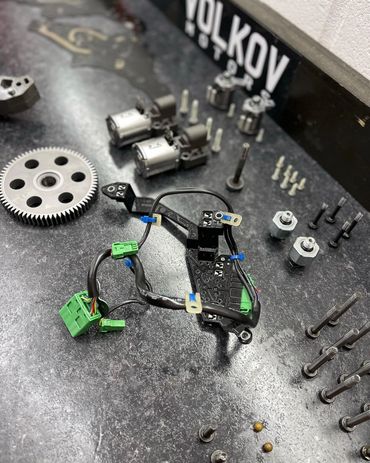

4. TCU Calibration Is Essential

We custom-tune the TCU (transmission control unit) to optimise clutch pressure, shift timing, and reliability under high load.

5. Built with Micron-Level Precision

Every transmission is carefully shimmed and blueprinted in-house to ensure perfect tolerances and long-term reliability.

6. Dyno & Track Proven

All builds are validated on our Mainline ProHub dyno (3000+ whp capable) and tested in real-world competition: Time Attack UK & RaceWars UK.

7. Modular Options Based on Your Goals

Not all builds are the same. We offer tailored options for street, drag, or full race applications — based on your power level and driving style.

Precision servicing for GR6 longevity, shift quality, and performance.

Why It’s Important

The main and oil pump valve body in the GR6 controls vital hydraulic pressure for clutch engagement and gear shifts. Over time, wear, fluid contamination, and heat cycles degrade performance — especially in high-power GTRs.

If left unchecked, this can cause slow shifts, pressure loss, or premature gearbox failure.

We disassemble, test, inspect, and rebuild your valve body with OEM and upgraded components, restoring consistent pressure and track-ready reliability.

Circlips are the retaining rings that hold key components like gears, clutches, and baskets in precise alignment inside the GR6 transmission. On stock GTR GR6 Gearset — especially under high torque and aggressive launches — these factory circlips are known to stretch, walk, or fail, leading to catastrophic internal transmission damage.

That’s why we install upgraded heavy-duty circlips on every high-power GR6 build. These stronger, heat-treated components provide increased retention strength, superior resistance to flex and fatigue, and significantly reduce the risk of internal gearbox failure during hard use.

Installed in-house during GR6 assembly at VOLKOV Motors

The GTR ETS also known as the FWD clutch — plays a critical role in distributing torque to the front wheels when traction demands it. But in high-power GTRs, the factory clutch pack often becomes a weak link, suffering from slip, overheating, and eventual failure under aggressive launches or circuit abuse.

We upgrade the ETS clutch using a track-proven formula developed through our own success in Time Attack and RaceWars UK. Every build includes essential reliability upgrades like a ball bearing retainer to prevent internal failure — a common issue in hard-driven GR6 units.

We set our own preload for optimal front torque engagement and ensure thermal stability with improved pressure and temperature control — key to delivering reliable performance lap after lap, run after run.

GR6 Main Clutch Upgrades – Matched to Your Power & Purpose

The stock GR6 clutch packs in the R35 GTR are surprisingly capable — often holding 800+bhp reliably when properly calibrated. But that’s only part of the story.

We know that the real weak points are often overlooked:

Clutch baskets can crack or flex under repeated launches or sustained torque, leading to clutch wear, slip, or failure.

Clutch seals can degrade over time, causing pressure loss and inconsistent engagement — especially in cars that see regular track time or hard launches.

That’s why, when we build a GR6, we inspect and upgrade far beyond the clutches themselves. Whether you’re aiming for 850bhp or 1,500+bhp, we recommend the right clutch pack, baskets, and supporting components — all installed and set up with our track-tested formula.

We completed GR6 swap including service, ETS FWD clutch rebuild, transmission solenoid valve body pack strip and clean and fast street geometry set up.

GR6 service and faulty solenoid diagnostics and replacement.

GR6 transmission service including x2 solenoid pressure sensors and main inline pressure sensor diagnostics supply and replacement.